小件多品种小批量快换夹具应用解决方案

小件机加工工艺,多工位夹持案例,零点多工位应用方案,零点夹具方案。

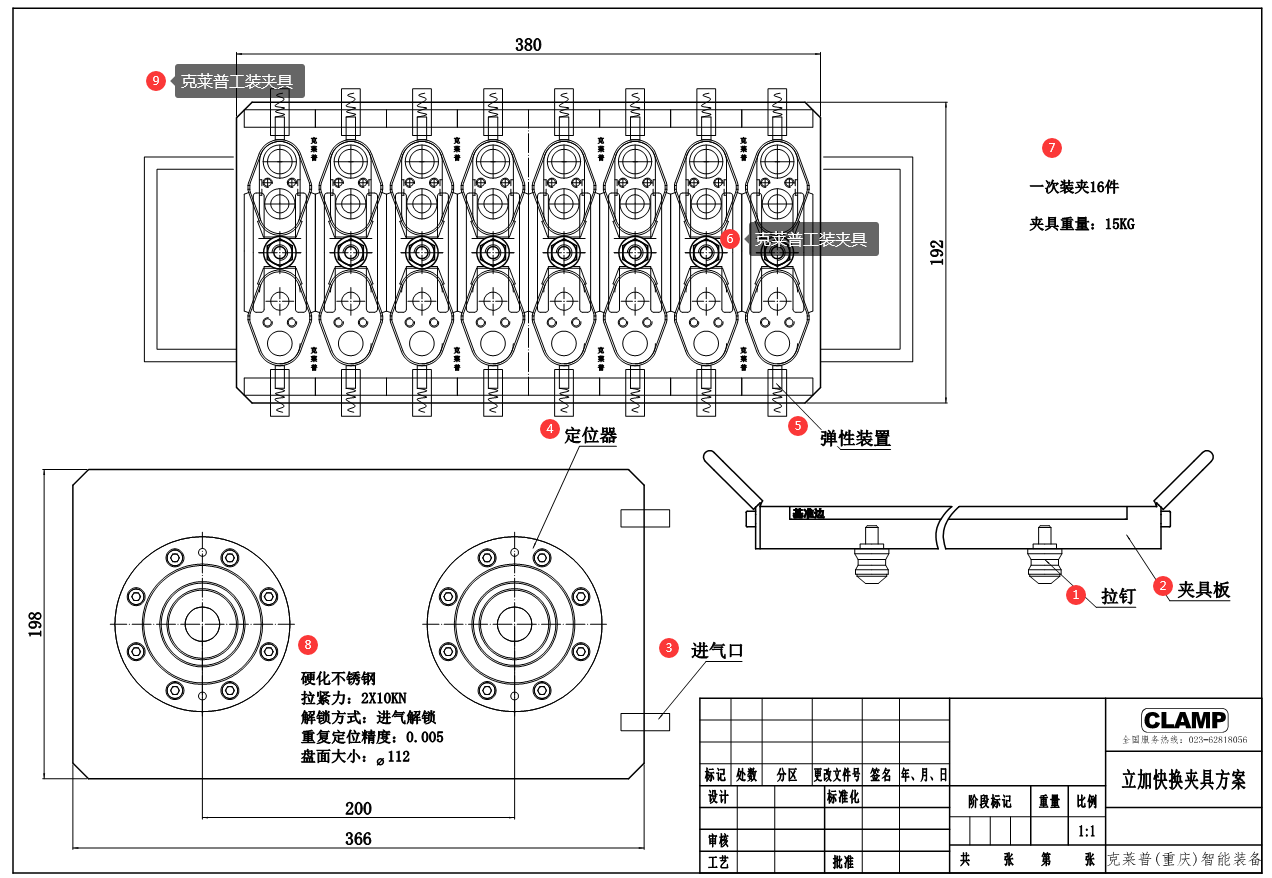

设计一次装夹16件

夹具重量:13KG![]()

夹具采用离线装夹的形式,采取机外装夹,机内加工,实现机床的不停机加工,可以最大化的降低机床的停机时间,目前我司在工装夹具的柔性化上面不惜余力的进行方案的敲定和打磨,力争为现代机加工企业带来实惠低成本性价比的解决方案。 我们擅长工装夹具,并对他进行改进和优化,直到满足客户的要求,通过我们的改善,客户的综合成本降低36.5%,效率提升46.5%.

同时增强了客户的机床的柔性化,能够在快速换型的情况下,进行很多产品的综合排布,直到满足订单的需求。

Design one time clamping 16 pieces

Fixture weight: 13kg

The fixture adopts the form of off-line clamping, adopts external clamping and internal processing to realize the non-stop processing of the machine tool, which can minimize the downtime of the machine tool. At present, our company spare no effort to determine and polish the scheme on the flexibility of the fixture, and strive to bring a practical and low-cost cost cost-effective solution for modern machining enterprises. We are good at fixture, and improve and optimize it to meet the requirements of customers. Through our improvement, the comprehensive cost of customers is reduced by 36.5%, and the efficiency is increased by 46.5%

At the same time, it enhances the flexibility of the customer's machine tools, and can carry out the comprehensive layout of many products in the case of rapid model change until the demand of the order is met.

夹具采用双工位零点定位系统,零点定位系统采用硬化不锈钢,拉紧力:2X10KN

,解锁方式:进气解锁,重复定位精度:0.005,盘面大小:∅112,采用断气夹持的形式,目前我司对零点应用非常广泛,如有各种领域的难度,高度使用情景,可以与我们讨论。

The fixture adopts duplex position zero positioning system, and the zero positioning system adopts hardened stainless steel, and the tension force is 2x10kn

, unlocking mode: air intake unlocking, repeated positioning accuracy: 0.005, disk size: ≈ 112, adopting the form of air cut clamping. At present, our company has a very wide application of zero point. If there are difficulties in various fields and high use scenarios, we can discuss them with us.